Kubernetes Ingress Controller Resources ¶ You’d need to map some local directory to that path to easily use the files inside this path: add -volume to your k3d cluster create command. in your user home directory for you to use. In k3d, the local paths that the local-path-provisioner uses (default is /var/lib/rancher/k3s/storage) lies inside the container’s filesystem, meaning that by default it’s not mapped somewhere e.g. There’s a PR in progress to make customizations easier (for k3d and for users): local-path-provisioner ¶ĭynamically provisioning persistent local storage with Kubernetes Resources ¶ resolve DNS queries using your local resolver). Modifications ¶Īs of k3d v5.x, k3d injects entries to the NodeHosts (basically a hosts file similar to /etc/hosts in Linux, which is managed by K3s) to enable Pods in the cluster to resolve the names of other containers in the same docker network (cluster network) and a special entry called which resolves to the IP of the network gateway (can be used to e.g. etc/nf configured in the Corefile doesn’t work the same, as the /etc/nf file inside the K3s node containers is not the same as the one on your local machine.

One thing to note though is, that the default forward. Note: it includes template variables (like %%) that will be replaced by K3s before writing the file to the filesystemīasically, CoreDNS works the same in k3d as it does in other clusters.Customizing packaged Components with HelmChartConfig:.volume /path/to/my/custom/coredns.yaml:/var/lib/rancher/k3s/server/manifests/coredns.yaml will override the packaged CoreDNS component. Note: /var/lib/rancher/k3s/server/manifests is also the path inside the K3s container filesystem, where all built-in component manifests are, so you can override them or provide your own variants by mounting files there, e.g.Automatically Deploying Manifests and Helm Charts:.

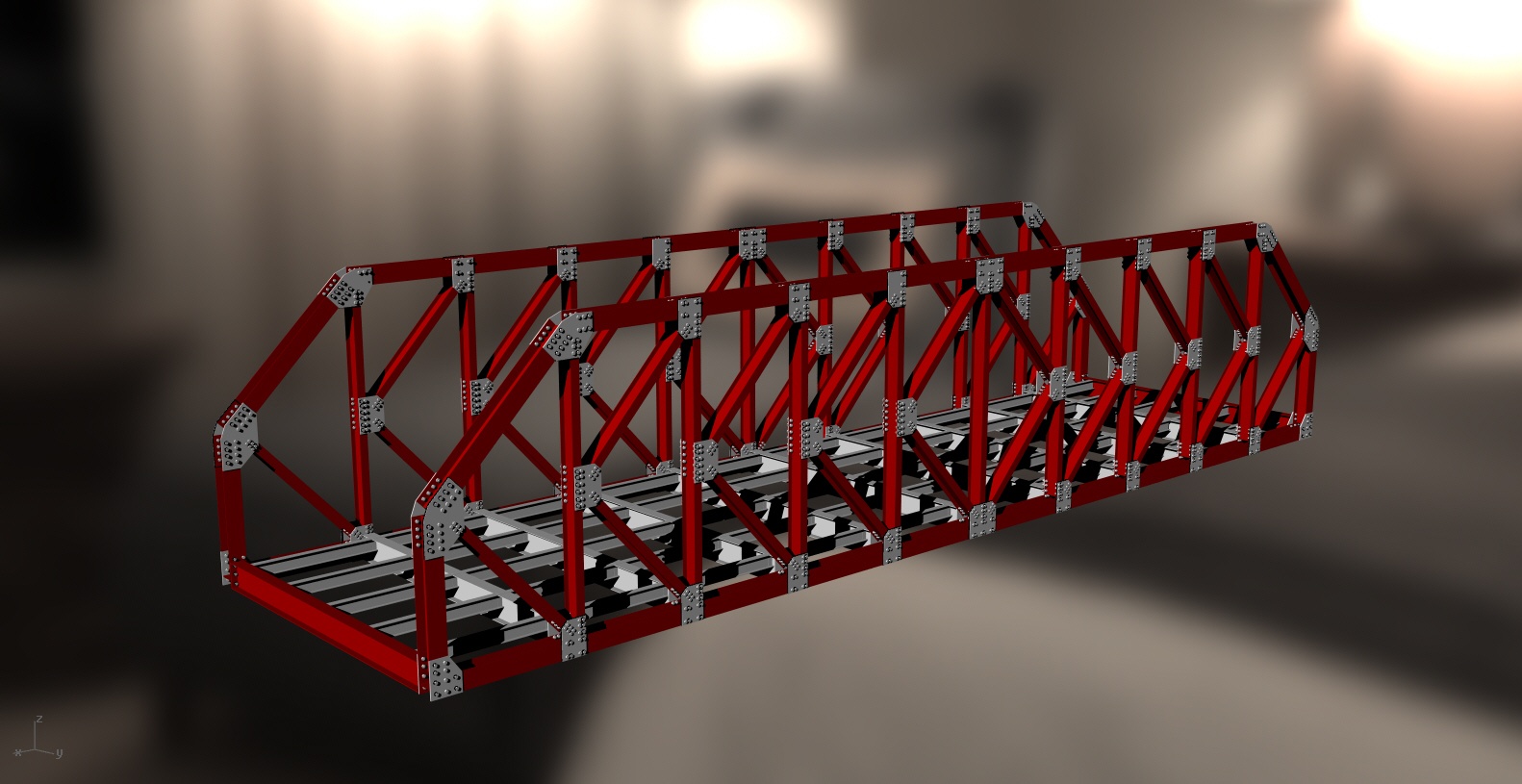

#K 3d measure software#

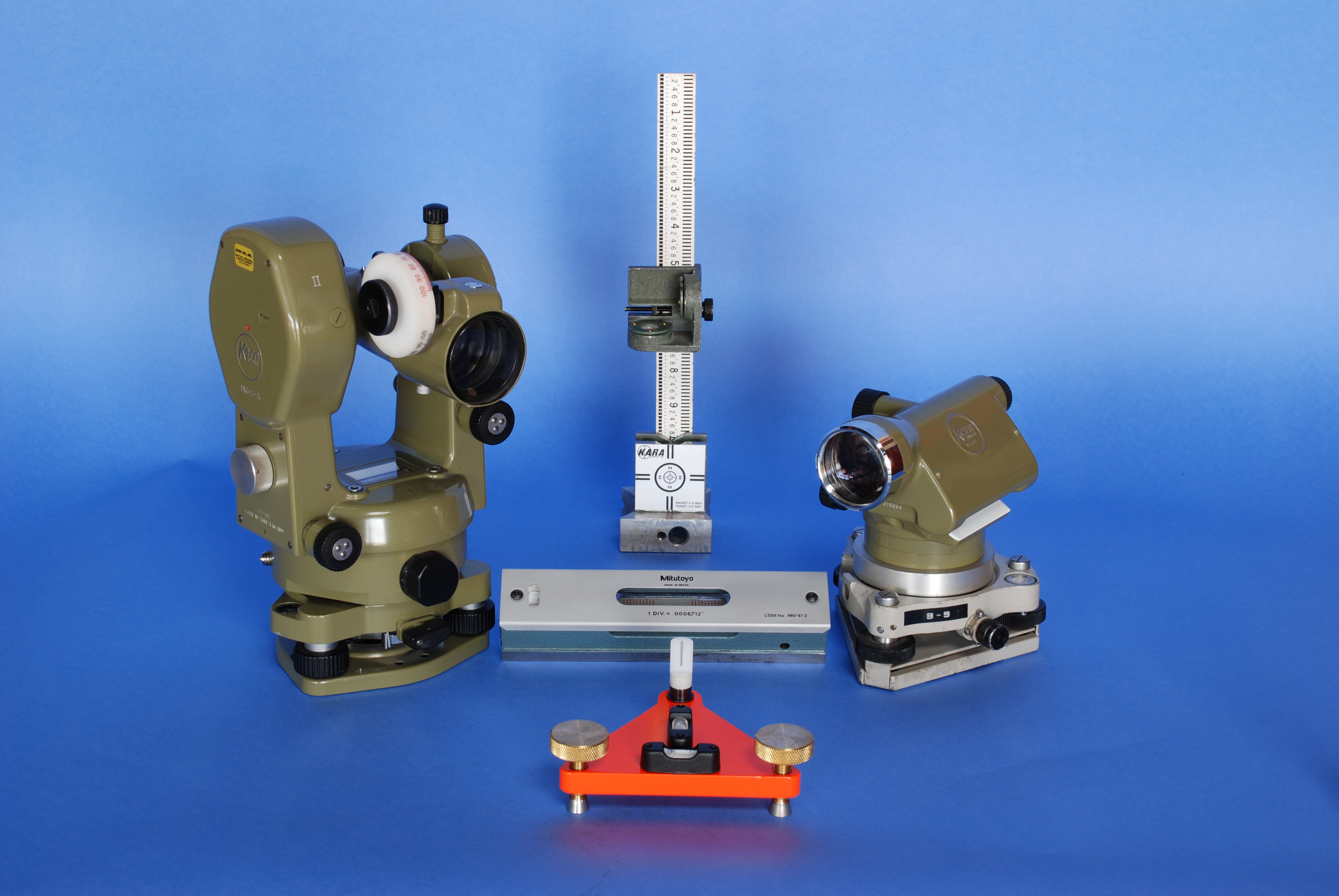

Use the cloud of points you acquire with the probe with the latest CAD/CAM software to enhance your work in untold ways, such as scaling-up, scaling down, merging pieces, personalizing products, amending defects, correcting for surface irregularities, and on and on.K3s ships with lots of built-in features and services, some of which may only be used in “non-normal” ways in k3d due to the fact that K3s is running in containers. Automate what would otherwise be a very tedious and time-consuming task. With the fast zero-point acquisition, workpiece digitization and copying, surface flatness acquisition, the ability to scan workpieces and perform impeccable quality control, you have the opportunity to reduce setup times, increase machine usage, and improve the dimensional accuracy and precision of your finished workĮliminate approximation and human error from your measurements. It would be hard to overstate the utility of a touch probe in the stone-cutting industry. Probing directions:Įlectronic high-speed switch with normally closed contact The cable has two wires, one the signal wire, the other ground. The signal is isolated from the instrument body. After the stylus is actuated, the contacts disconnect. The internal electrical connection resembles a simple switch with normally connected contacts having a resistance of 10-30 Ω when closed. It clamps to the spindle via an 8 mm ER collet which you can conveniently purchase at Wiring The connecting shank has a diameter of 7 mm and is 20 mm long. Unlike cheap hobby probes, this probe allows mechanical calibration to align the probe axis perfectly with the spindle axis once calibrated, it is secured in position with 4 set screws (Allen screws). The probe is IP64 certificated and is therefore dust-tight and able to operate safely in wet environments, i.e.

Our Amastone touch probe is made of high-quality anodized aluminum and stainless steel.

0 kommentar(er)

0 kommentar(er)